Home / All

News Group

News

- Factors affecting dry bulk density of spray dryerSpray dryer is a drying equipment for treating solution, suspension or slurry material. It can be directly dried from liquid to powder, which is the biggest advantage of spray dryer. Its low thermal efficiency, large volume, low production capacity and high investment are its shortcomings. Spray drying machine is widely used in chemical industry, light industry and food industry because it can be directly obtained from solution or suspension system with uniform powder products.Oct 28,2020

- Advantages and disadvantages of vibrating fluidized bed and energy saving measuresVibrating fluidized bed is a conventional equipment for drying in pharmaceutical industry, which belongs to the type of convective drying. The working mechanism of the flow dryer is that the heat is directly transferred to the wet material by hot air convection, and the water vapor is taken away at the same time when the moisture vaporizes. Besides the dryer itself, the device also has fan, heater, separator and other auxiliary equipment.Oct 28,2020

- 3D mixer plays an important role in mixer MarketMany pharmaceutical, chemical, light industry and other industries will use mixing equipment, mainly including: V-type mixer, double cone mixer, 2D mixer and 3D mixer, etc. Among them, 3D mixer occupies an important position.Oct 19,2020

- Comparison Of Advantages And Disadvantages Of MixerMixing is an indispensable production process in modern industry. With the continuous development of industry, the development of mixer will be more and more powerful. Mixer covers the entire industrial field, such as chemical industry, food, building materials, medicine, chemical fertilizer. There are many kinds of powder mixing equipment. The advantages and disadvantages of mechanical mixing equipment are analyzed below.Oct 10,2020

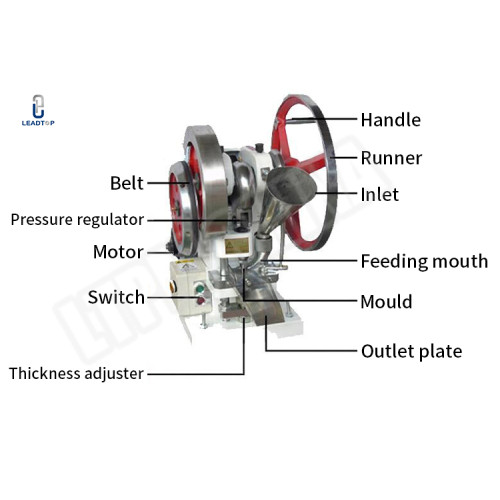

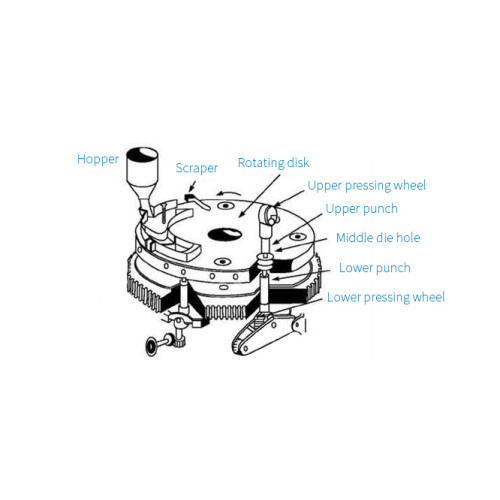

- What is a tablet press machine?A tablet press, also known as a tablet compressing machine or tableting machine, is used to compress pharmaceutical powder formulations into tablet form, creating tablets of uniform size, shape and weight. The tablet press may also be used for the manufacture of products in the form of tablets for other sectors such cosmetics, cleaning products and catalysts for the petrochemical industry.Sep 23,2020

- Fluid bed granulator: Although there are many advantages, the influencing factors also need to be paid attention toFluid bed granulator is also called one-step granulator. It is a machine which can complete the mixing, granulation and drying of conventional wet granulation in a closed container at one time. The Fluid bed granulator can keep the drug powder in suspension fluidization state under the action of bottom-up air flow. The adhesive liquid will be sprayed into the fluidization chamber from the upper or lower part, and the powder will agglomerate into particles.Sep 23,2020

- How to improve mixer efficiency?At present, there are spiral belt mixer, cone mixer, V-type mixer and three-dimensional mixer which are popular in the market. For mixer users, the quality, uniformity and efficiency of mixing materials are the main concerns, among which the efficiency has attracted much attention in recent years. Therefore, improving the efficiency of mixer is the key to win in the market. What factors can we improve the efficiency of the mixer? The author summarizes the following aspects.Sep 21,2020

- spray dryer cleaning and maintenance are fastidious, these commonly used methods must be kept firmly in mind.Spray dryer is a device that can dry and granulate at the same time. It mainly consists of slurry supply system, atomizer, drying tower, hot air system, exhaust gas and dust removal system, unloading and powder conveying system.Sep 16,2020

- Advantages and disadvantages of vibrating fluidized bed and energy saving measuresVibrating fluidized bed is a conventional equipment for drying in pharmaceutical industry, which belongs to the type of convective drying. The working mechanism of the convective dryer is that the heat is directly transferred to the wet materials by hot air in the form of convection, and the water vapor is taken away at the same time when the moisture vaporizes. Besides the dryer itself, the device also has fan, heater, separator and other auxiliary equipment.Sep 9,2020

- Comparison of methods and advantages and disadvantages of spray dryerSpray dryer is easy to operate, excellent in performance and excellent in manufacturing, especially in meeting the requirements of GMP in pharmaceutical and food industries. It is welcomed by users in the pharmaceutical and food industries.Sep 9,2020

- Analysis on the problems of hard particles, uneven particle size and roll of dry granulatorIn the production process of granule medicine, granulator such as dry granulator plays a key role. It is understood that the dry granulator can meet the requirements of one-step granulation, integrate the tedious processing links together, and carry out completely closed processing, so that the appearance of the processed granule medicine is improved, and it is easy to store and transport.Aug 26,2020

- What should be done if the pressed tablets can not be disintegrated within the prescribed time limitIn the production process of the tablet press machine, there are often cases where the compressed tablets cannot be disintegrated within the prescribed time limit, which affects the dissolution, absorption and efficacy of the drug. What is going on? How to solve it?Aug 26,2020

- High speed mixing granulator how to reduce heat loss? try this optimization!In the production of solid preparation tablets, mixing and granulation are the key to determine the quality of compression tablets or capsules. In a sense, granulation is the key basis. In the past, wet granulation equipment was widely used in the industry, but now wet granulation equipment has developed to high-speed mixing granulator, which is a kind of solid preparation pharmaceutical equipment which develops rapidly in recent years.Aug 18,2020

- How to improve the filling quality of capsule filling machine Pay attention to these stationsIt is reported that some pharmaceutical companies in the process of producing capsules, due to the fine powder, will produce appearance defects during machine filling, which has always been required to remove by manual "drug selection". Through continuous optimization and debugging of the capsule filling equipment, the product rate of appearance defects is reduced, and the labor cost is greatly reduced.Aug 12,2020

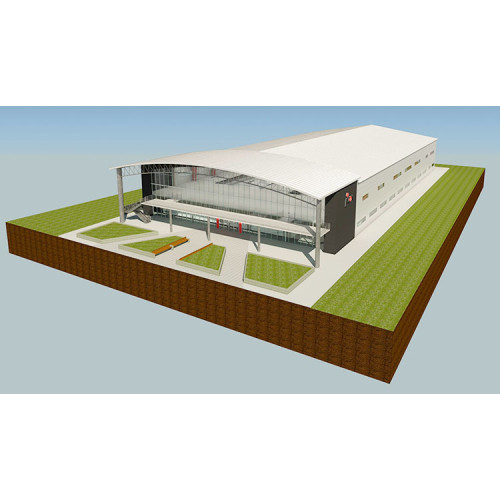

- What aspects should be paid attention to to build a clean medical workshop?The pharmaceutical industry is a high-pollution industry. In recent years, with the advancement of environmental protection policies, there are not a few pharmaceutical companies that have "slopped" on environmental issues. Due to the difficulty and high cost of pollution control. At present, how to solve the problem of economic and environmental benefits has become a topic that pharmaceutical companies have to face.Aug 3,2020

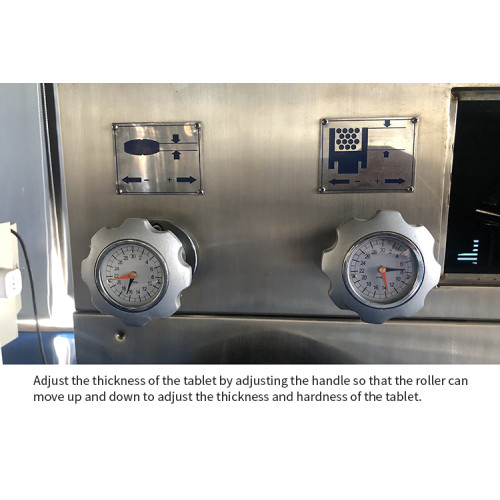

- How to debug the medicine tablet machine Three simple tutorials are worth referring toThe tablet press is a machine that puts granular or powdery materials in the die hole and presses them into tablets.Jul 30,2020

- How to improve the coating success rate is the keyThe purpose of coating is to improve the appearance of the tablet, prevent moisture, avoid light, cover up bitterness or unpleasant odor, and control the release location and release rate of the drug.Jul 30,2020

- The use of Single Punch Tablet Press, these maintenance knowledge is essentialIn the pharmaceutical industry, the single punch tablet machine can be said to be an indispensable processing equipment, usually used to compress various Chinese medicine tablets, western medicine tablets, etc.Jul 30,2020

- How to choose the mixer to achieve the expected mixing effectIn the process of medicine and other industrial production, mixer is a common equipment. Its function is to mix two or more materials evenly. In recent years, with the rapid development of pharmaceutical industry, mixer equipment also ushered in the objective market prospects. At present, three-dimensional mixer and two-dimensional mixer are common in the market.Jul 30,2020

- What are the advantages and disadvantages of the three common extrusion granulators?Granulation refers to the operation of processing materials in the state of powder, melt, aqueous solution, etc. into granules with a certain shape and size. At present, the granulation processes used by pharmaceutical companies include extrusion granulation and shear granulation.Jul 30,2020

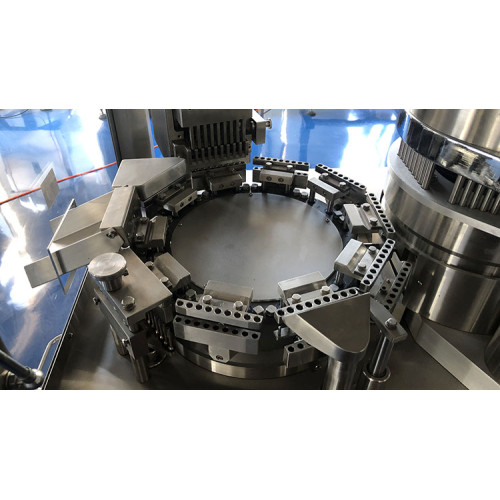

- Regulating mechanism of automatic tablet press machineThe filling dose adjustment on the rotary tablet press is mainly based on the filling rail. By rotating the dial regulating plate, the shaft can be driven to rotate, and the worm shaft connected with it also rotates.Jun 29,2020

- The diversified requirements of the rotary tablet press structure:In the customized orders of users, the diversified requirements for the structure of the tablet press are mainly manifested in the following aspects:Jun 22,2020

- The diversified requirements of the rotary tablet press structure:In the customized orders of users, the diversified requirements for the structure of the tablet press are mainly manifested in the following aspects:Jun 22,2020

- The Selection Of Materials For Effervescent Tablet PressingEffervescent tablet pressing machine is a kind of automatic rotating and continuous tablet pressing machine. It is also a special equipment for chemical, food, electronic and other industrial enterprises to press granular raw materials into tablets or granules, which is suitable for small batch production.Jun 19,2020

- What is a single station tablet press and how does it work?A single station tablet press is a simple mechanical machine that can be used to compress powder into tablets that are uniform in size, shape and weight. The machine is used for low-volume production of tablets for a wide range of applications from cosmetics and pharmaceuticals to cleaning products.Jun 19,2020

- The Different Types Of Tablet Coating MachinesTablet coating machines work on the simple principle of applying the coating ingredients in the form of a solution to a group of tablets in a bed that may move horizontally or vertically. A concurrent flow of heated air helps to evaporate the solvent. The coating is equally distributed to the tablets through the movement of the bed.May 28,2020

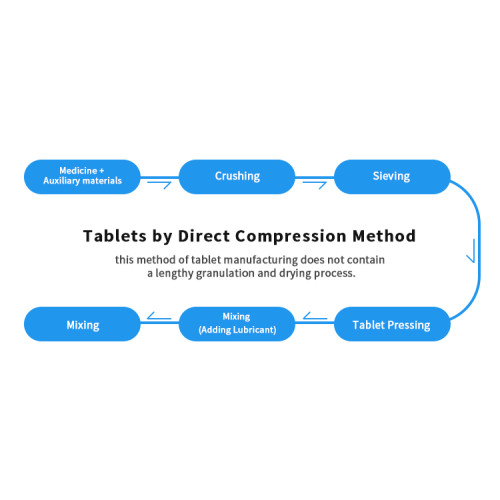

- Manufacturing of Tablets by Direct Compression MethodDirect compression method of tablet manufacturing is widely used because it is a time saving process. this method of tablet manufacturing does not contain a lengthy granulation and drying process.May 26,2020

- Causes and Remedies of Cracking in Tablet ManufacturingCracking in tablets during the compression is a major problem in tablet manufacturing. Some causes and solutions of the cracking of tablets are given here.May 25,2020

- Structure and principle of capsule filling MachineThe filling speed of capsule filling machine is faster and the size difference of capsule filling machine is small. In addition, capsule filling machine has many advantages, such as fast arrangement speed, high efficiency, simple operation, convenient maintenance, low power consumption and so on. It is the first choice capsule filling machine for pharmaceutical factory, health product factory, hospital preparation room.May 25,2020

- Daily Maintenance And Common Failure Analysis Of Capsule Filling MachineIn the pharmaceutical industry, the capsule filling machine is a kind of commonly used equipment, which can carry out automatic transmission, seeding, filling, locking and other processes for capsules.May 12,2020

Please send your message to us

- Mobile Phone

- *Title

- *Content

CONTACT US

subscription