Structure and principle of capsule filling Machine

Structure and principle of capsule filling Machine

The filling speed of capsule filling machine is faster and the size difference of capsule filling machine is small. In addition, capsule filling machine has many advantages, such as fast arrangement speed, high efficiency, simple operation, convenient maintenance, low power consumption and so on. It is the first choice capsule filling machine for pharmaceutical factory, health product factory, hospital preparation room

Structure of automatic capsule filling Machine

The automatic capsule filling machine consists of the empty capsule feeding device, the capsule distributing device, the powder discharging device, the metering disk mechanism, the capsule filling sealing mechanism, the main transmission mechanism in the box and the electrical control system.

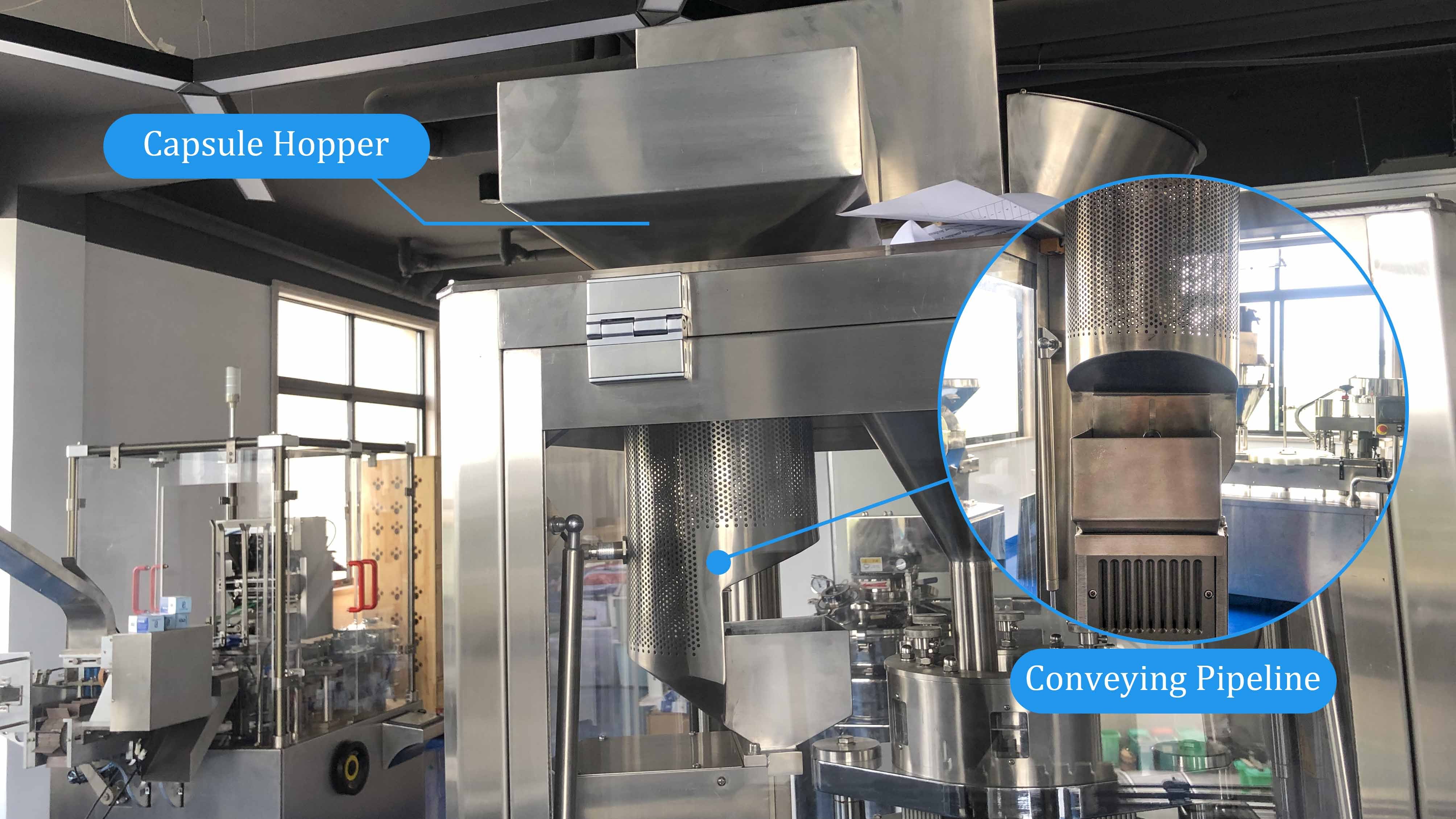

1 Empty capsule feeding device: consisting of hopper and conveying pipeline, mainly storing empty capsule and making empty capsule vertically enter the capsule subdivision device one by one.

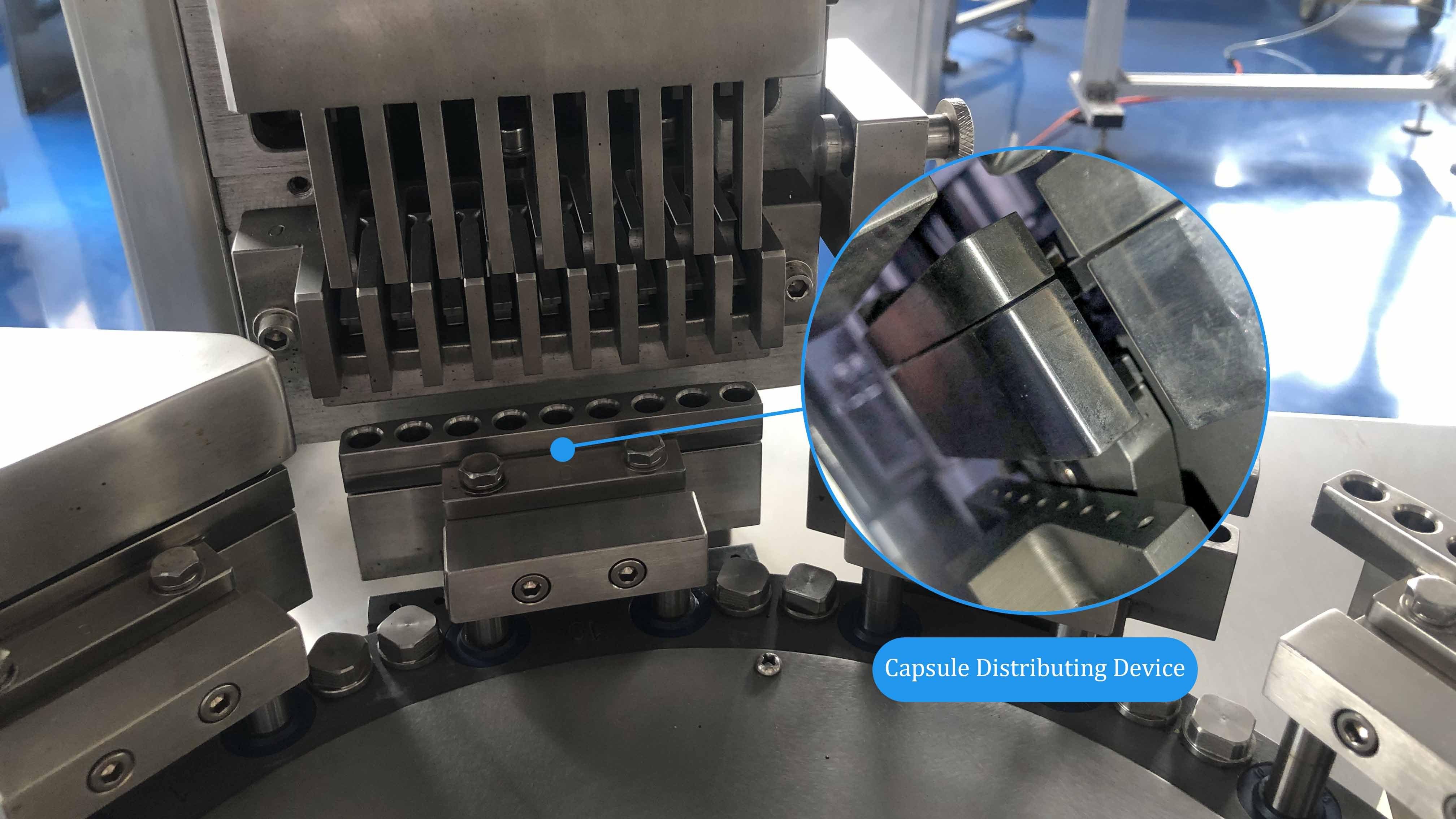

2 capsule distributing device: making empty capsule enter the optional fork of distribution device, Optional fork down action will send six capsules at a time, and the plastic cap on the top. At the same time, the vacuum separation system puts the capsule into the module and separates the body cap.

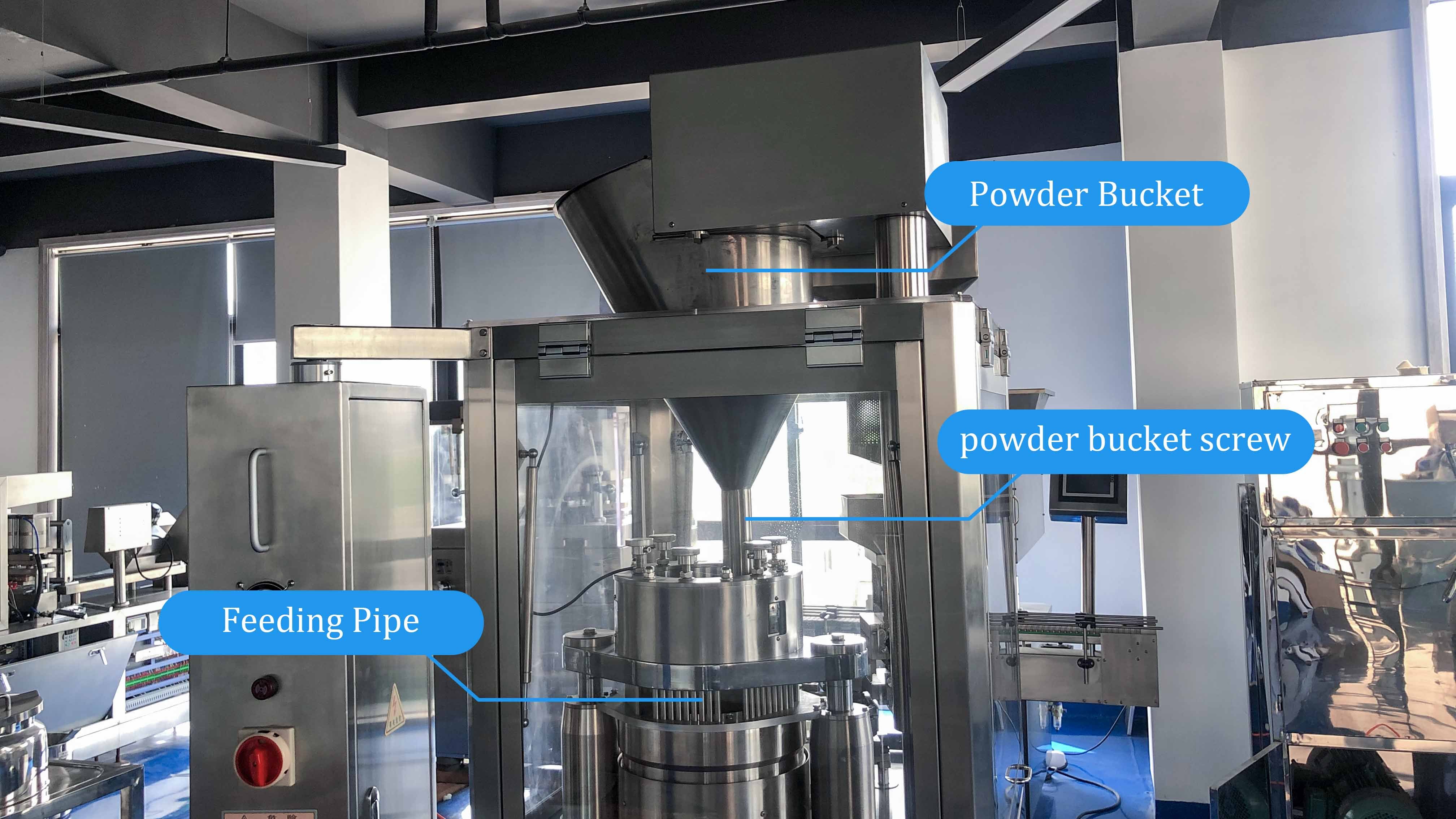

3 powder discharging device: it is composed of powder bucket, powder bucket screw, feeding pipe and so on. The powder stored under the action of screw and agitation is controlled on the metering plate.

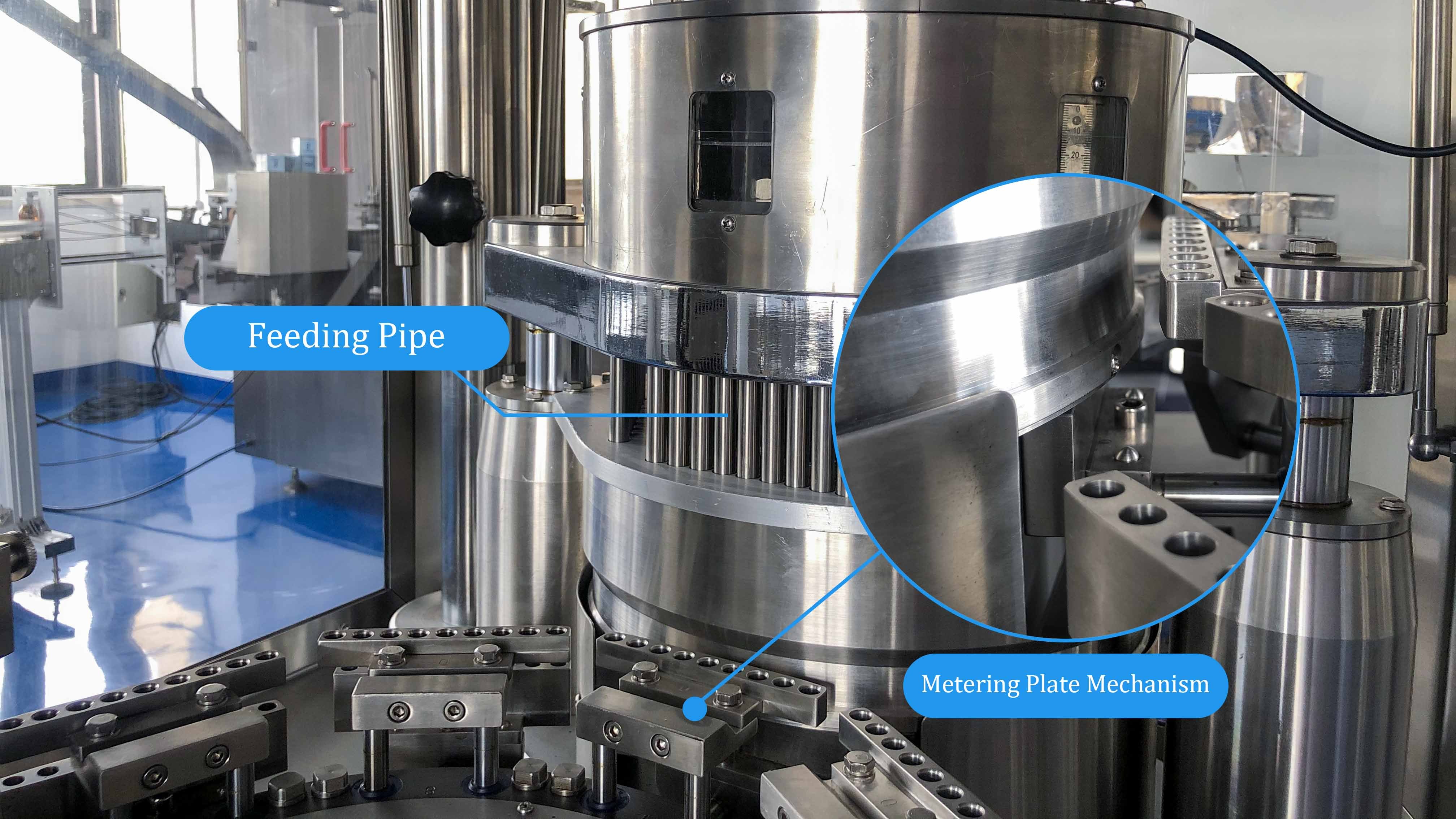

4 metering plate mechanism: according to the capsule specifications and the volume of the matching metering plate specifications. The powder is filled with compacted columns five times in an intermittent rotating metering plate and pushed into the capsule of the lower module.

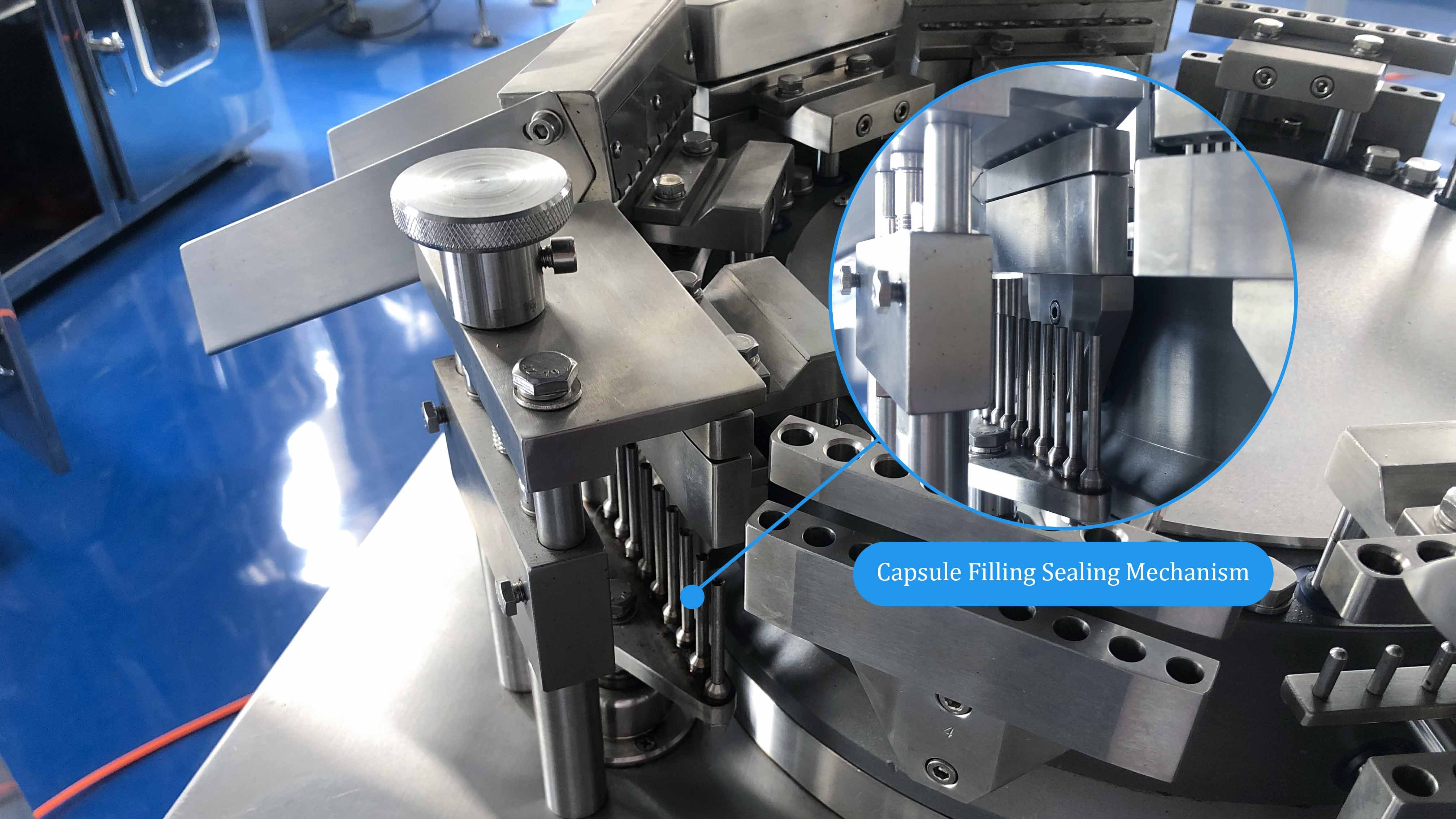

5 Capsule filling sealing mechanism: when the capsule body is pushed into the capsule, the upper and lower modules of the gel cap and the lower capsule body are pushed up to fasten the capsule body.

6 main transmission mechanism in the box: the motor in the box, the intermittent rotary mechanism of the box Ferguson, the gear pair, the deceleration, the cam pair and the chain transmission mechanism to complete the execution work, at the same time, Frequency conversion motor to achieve frequency control function.

7 electrical control system: PLC control system to display the technological elements of each capsule filling.

Principle of automatic capsule filling Machine

The main working principle of the automatic capsule filling machine is that when the machine is running, the capsules in the capsule hopper will vertically enter the delivery fork one by one. When the fork is sent down, six capsules are delivered at a time, and the cap is placed on top. In the first operation, the vacuum separation system puts the capsule into the module and separates the body cap. When the rotating plate rotates intermittently to the second work, the upper meter rises quickly and moves inward, the compacted medicine column is pushed into the capsule of the lower module on the fifth working filling rod, and the unseparated capsule is excluded from the eighth work. The upper and lower modules are combined on the tenth work, and the lower capsule body is pushed up so that it is fastened, and the finished product of the capsule will be released and collected in the eleven working positions. In the twelfth station, the vacuum cleaner cleaning module then enters the next cycle. The powder column is formed by filling and compacting five times in the intermittent rotating metering plate.