The use of Single Punch Tablet Press, these maintenance knowledge is essential

The use of Single Punch Tablet Press, these maintenance knowledge is essential

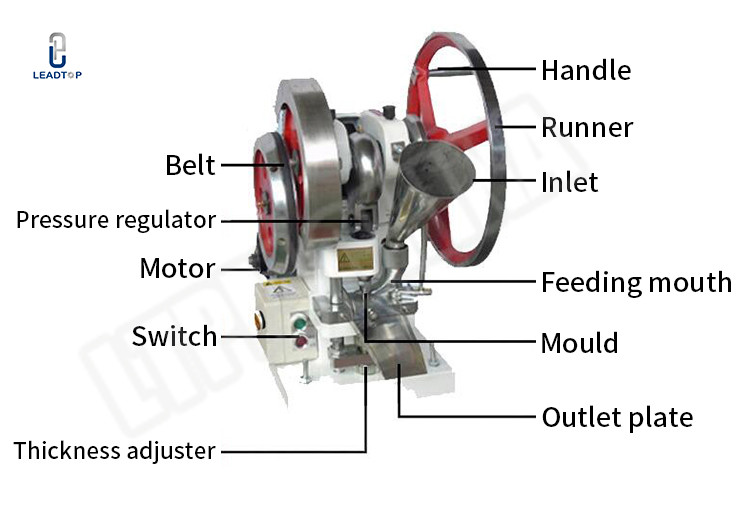

In the pharmaceutical industry, the single punch tablet machine can be said to be an indispensable processing equipment, usually used to compress various Chinese medicine tablets, western medicine tablets, etc. Due to its excellent performance, strong adaptability, convenient use, easy maintenance, small size, light weight, and the ability to shake tablets when there is no electricity, the single-punch tablet machine can meet the requirements of the pharmaceutical industry for suppressing various Chinese and Western medicines. , Deeply welcomed by the pharmaceutical industry.

When using a single-punch tablet machine, users need to pay attention to some things to ensure the normal operation of the equipment. For example, a single-punch tablet machine can only be operated in a certain direction (see the arrow on the hand wheel or the protective cover) and cannot be reversed, otherwise it is easy to avoid damage to the machine parts. The industry reminds that users need to pay special attention to this point when adjusting the press, and do not neglect.

For another example, the single-punch tablet presses on the market have manual tableting or electric tableting. Regardless of the type of tableting, the user should put the upper punch rod in the up position before starting. If it starts with the upper punch in the lowered position, it enters the middle-molded sheet at the beginning of the start. At this time, since the speed of the machine has not yet risen, the inertia is small, and it is prone to jacking.

The "top car" means that after the upper punch enters the middle mold, it "tops to death" due to the resistance of the tablet, causing the machine to stop. Due to the heavy load when jacking the car, it often damages the machine or burns the motor. Once this happens, the user should turn off the power immediately to avoid burning the motor. When the jacking truck is in a light condition, you can turn the hand wheel to make the upper punch pass through the "dead point"; when it is severely jacked, loosen the connecting rod locking nut and turn the upper punch rod to raise it to reduce the pressure. Then turn the handwheel to eject the tablets, and then readjust the hardness of the tablets.

In addition to mastering the use matters, equipment maintenance is also a "learning". It looks simple, but the actual operation is not easy. According to the industry, generally speaking, there are the following maintenance techniques for single-punch tablet machines.

First, the user must manually test and press a few tablets before and after the equipment is working, and then turn on the electric press after there is no problem.

Second, the issue of cleanliness needs attention. After using, the user should take out the remaining powder and wipe all parts of the machine. If the equipment is out of service for a long time, the die must be removed, the working surface of the equipment must be wiped clean, coated with anti-rust oil, and dust-proof clothing; the die should be cleaned and immersed in oil for storage.

Third, the lubrication of the friction surfaces of the moving parts is an important link to ensure the normal operation of the machine and prolong the service life. The industry pointed out that, especially the main moving parts, if they are running under the condition of lack of oil, they may quickly damage the equipment. Therefore, before using the tablet press, all oil cups, oil holes and friction surfaces must be lubricated and empty. When running, each friction surface is covered with oil film before it can be put into use.

In addition, it is necessary to add oil on time, but you should not add too much oil each time, so as not to overflow and affect cleaning and contaminate the tablets.

Fourth, check the parts regularly. Before each work, check whether the screws are loose or not, and always pay attention to check during the work. If they are loose, they should be tightened immediately to avoid malfunction.

Fifth, in the process of tablet pressing, the operator must frequently check the quality of the punching die. If there are missing edges, cracks, deformation, etc., they should be replaced in time to avoid malfunction, damage to the machine, and affect the quality of the tablet.