Fluid bed dryer granulation machine coffee roaster price

| Share | |

|---|---|

| Categories | Fluid Bed Dryer |

| Brand | LTPM CHINA |

| Model | FG-15 |

| Model | FLP-5 |

| Production capacity(kg\batch) | 1-5 |

| Temperature of inlet air (℃) | indoor ~100℃ adjusting |

| Power of fan | 4kw |

| Electric heater | 9kw |

| Total power | 13kw |

| Pressure of compressed air | 0.45Mpa |

| Consumption of compressed air | 0.6 cubic meters/min |

| Heating Method | Electric heating |

| Material of Parts | SS304 |

| Unit Price | US $ 31800 / piece |

| FOB port | Ningbo |

| Terms of Payment | L/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal |

| Update Time | Feb 13,2026 |

Fluid bed dryer granulation machine coffee roaster price

Application:

1.The FL series Boiling Fluid Bed Dryer can be widely used in pharmaceutical,chemical,foodstuff industry etc.

2.The FL series Boiling Fluid Bed Dryer is one of the standard process equipment in the solid preparation production.for example:the production of tablets,granules and other wet granules.

3.The FL series Boiling Fluid Bed Drye has many fuctions.such as mixing,granulating etc.and used for fast dry & wet mixing, homogenizing,humidifying and granulating of the powder.

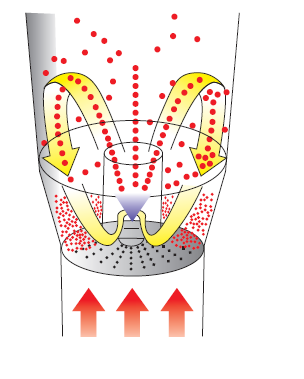

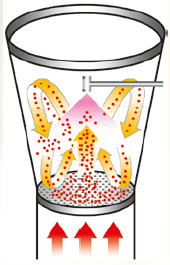

Working Principle:

1.The FG series Boiling Fluid Bed Drye is composed of main machine (processor), air handling unit(AHU), heating and control systems. When operating, charge the materials into the Bowl, set the procedure and parameters according to process requirements

2.Start the processor.The inlet air is filtered by the air handling unit(AHU)and heated by the heating system

3.The processed air enters the processor to blow up materials into fluidization condition. Materials are apace dried and moisture rapidly vaporized.

4.When the operation has been finished; Move out the Bowl to lock with pharma Lifter for FBD/FBG Bowl for lifting and discharging the produced granules.

5.During the whole process, powder dust and cross pollution are effectively controlled.

Top Fluiding:

Bottom Coating:

Main Technical Parameters:

Number | Item | Unit | Model/specification |

1 | Productive capacity | Kg/batch | 15 |

2 | Power of fan | Kw | 7.5 |

3 | Electric heater | Kw | 15 |

4 | Total power | Kw | 22.5 |

5 | Pressure of compressed air | Mpa | 0.4-0.7 |

6 | Consumption of compressed air | M3/min | 0.6 |

Machine Picture:

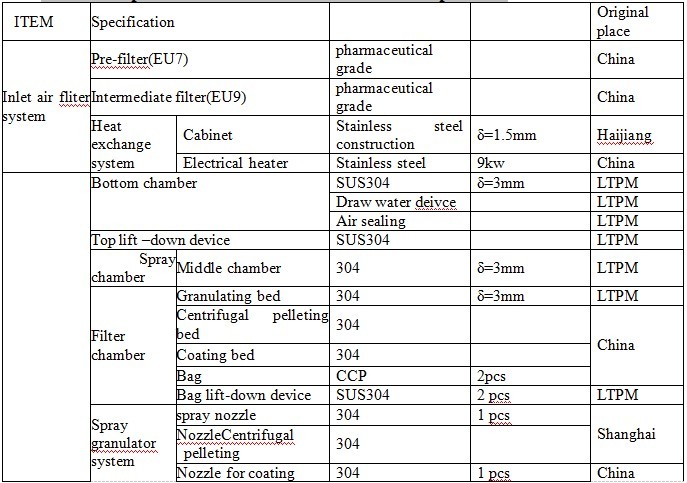

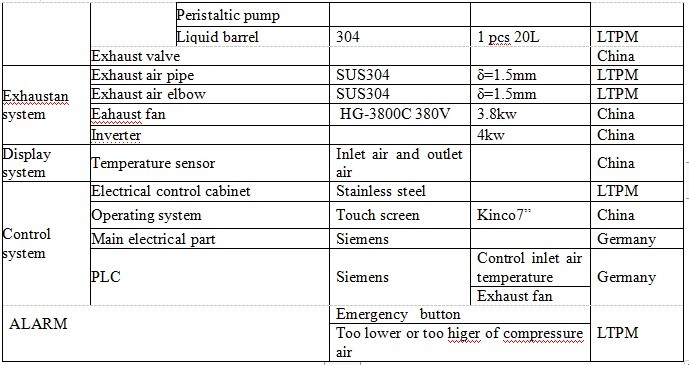

The Basic Options which are included in the complete set:

Easy Damaged Parts (2 years):

Item | Number | Place of production |

Bag filter | 2sets | LTPM |

Silicon sealing | 20m | |

Silicon sealing | 20m | |

Pressure tube | 240m | Market product |

- Phone

- *Title

- *Content

- Phone

- *Title

- *Content