LPG-10 Lab mini spray dryer equipment for milk instant coffee powder

| Share | |

|---|---|

| Categories | Spray Drying Machine |

| Brand | LTPM CHINA |

| Model | LPG-10 |

| Water Evaporation | 10kg/h |

| Method of Atomizing | High Speed Centrifugal Atomizer (mechanical drive |

| Revolution of atomizer(rpm) | 22500 |

| Diameter of Atomizing disc (mm) | 60 |

| Dried Powder Recovery Rate (%) | Around≥95 |

| Length of Covered Area(m) | 1.7 |

| Width of Covered Area(m) | 1.2 |

| Height of Tower Body(m) | 2 |

| Tower Height | 2000mm |

| Air input Temp | 160~200℃ |

| Air output Temp | 70~90℃ |

| Unit Price | US $ 20800 / piece |

| FOB port | Ningbo |

| Terms of Payment | L/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal |

| Update Time | Feb 25,2026 |

LPG-10 Lab mini spray dryer equipment for milk instant coffee powder

Machine Description:

Spray drying is the most wide applied process in liquid process shaping and drying industry.The drying technology is most suitable for producing solid powder or practical products from liquid material,such as :solution,emulsion,suspension and pumpable paste states.For this reason,the particle size and distribution of the final products,residual water contents,mass density and the particle shape must meet the precise standard,spray drying is one of the most desired technologies.

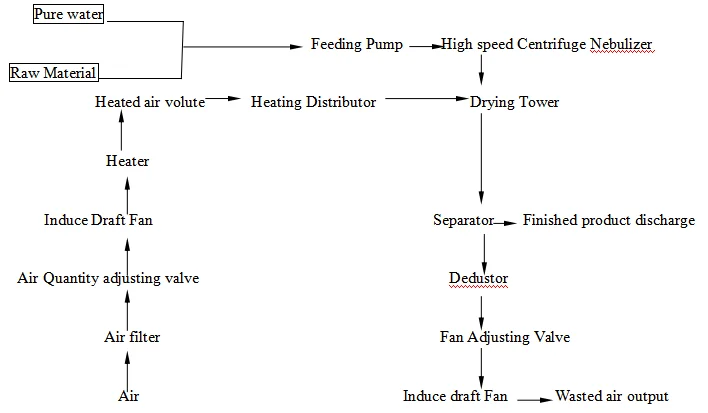

Working Principle:

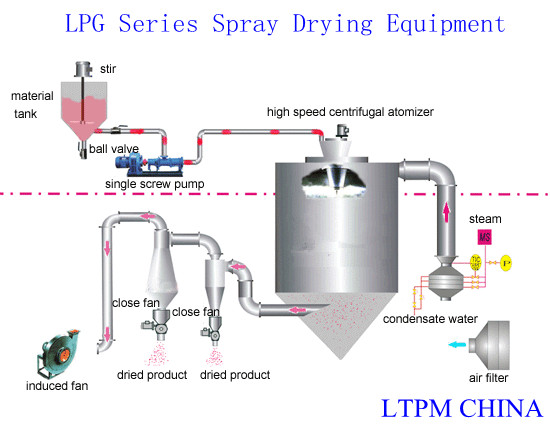

After air gets filtered and heated,it enters into an air distributor on the top of the dryer.The hot air enters into the drying room in a uniformly spiral form.Passing through the high speed centrifugal sprayer on the top of the tower,the material liquid will rotate and be sprayed into the extremely fine mist liquid beads.Through a very short time of contacting the hot air,materials get dried.The final products discharge continuously from the bottom of the drying tower and from the cyclones.The waste gas will be discharged from blower.

Machine Structure Consist:

This procession equipment includes five different structures: Feeding System, Heating System, and Drying System, collecting system and electronic controlling system.

a)、Feeding System:

Morrow pump is adopted on feeding pump which speed can be adjusted. It meets to the special requirement from Starting Temp increasing, Stop Temp decreasing and stable material feeding when machine running.

The speed of the Nebulizer can be reached higher than 120m/s by two grades motor transport with two grades gear speed up. It can atomize raw material fast, continuously and uniform. The surface area of granule increased and exchange heating with clean hot air, and the moisture took away by induce draft fan.

b)、Heating System:

The hot air use to drying is filtered clean air. The first filter is non-woven special for prevent bugs fly into drying tower. The second filter us also made from non-woven, filter accuracy is less than 5micron. The resistance of second filter is ≤15mmH2O. It is special for filter dust in the air to prevent to pollute products. The third filter reaches 100,000class clean.The heating processing adopts Steam heating with electronic heating(36KW) compensate.

c)、Drying Station:

The drying station consist by Hot Air Volute, Hot air distributor, inner tower, Tower structure, Outer Tower, Material discharge pipe, heat preservation materials, cleaning door and light hole. The cleaned hot air come out from heating device goes through hot air volute to hot air distributor then goes to drying tower uniformly. The rotation position of hot air distributor can be adjusted from 0 degrees to 30degrees. There is one View and clean door equipped on drying tower, the light is equipped on the top of the inner tower for lightening whole tower. The heating preservation materials are made from aluminum silicate with 60mm thickness.

d)、Collecting System:

The collecting system consist by First grade separator and second grade separator. It can collect 93-97% powders, the others will be collected by dedustor. The discharge style is vacuum valve discharge.

Drying Process:

Controlling System:

The electronic box is made from SS304, and PLC is adopted for controlling system. All of the data are displayed on touch screen. And the main electronic parts are all imported brands.

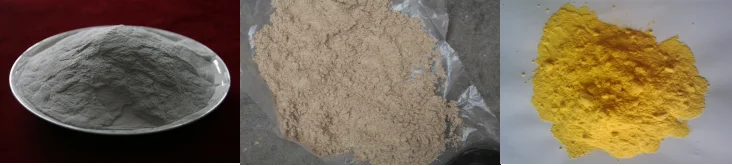

Finished Products:

Alumina Powder Herbal Powder Egg Powder

Milk Powder Soy Sauce Powder Polyphenols

Main Techinical Data:

Item | Specification |

Water Evaporation | 10kg/h |

Method of Atomizing | High Speed Centrifugal Atomizer (mechanical drive or stepless frequency speed regulation is available) |

Revolution of atomizer(rpm) | 22500 |

Diameter of Atomizing disc (mm) | 60 |

Dried Powder Recovery Rate (%) | Around≥95 |

Length of Covered Area(m) | 1.7 |

Width of Covered Area(m) | 1.2 |

Height of Tower Body(m) | 2 |

Hoisting height of Nozzle(m) | -- |

Air input Temp | 160~200℃ |

Air output Temp | 70~90℃ |

Tower Height | 2000mm |

Notes: The evaporated amount of moisture is contingent upon the characteristics of the raw material, solid content and temperature of hot air at inlet and outlet. Customers can choose the heating method according to the conditions of the local energy source. | |

Machine Pictures:

- Phone

- *Title

- *Content

- Phone

- *Title

- *Content